Innovative Equipment Engineered to Last

Discover Barreto Manufacturing's 40 years of innovative, durable landscaping equipment, along with expert tips and local highlights for your projects.

Building Barreto Tough: Laser Department and Press Brake

Barreto Manufacturing equipment is proudly made in the USA, and over 95% of our manufactured parts and components are fabricated in-house. In this article, we are going to give a bit of insight on how we build Barreto equipment.

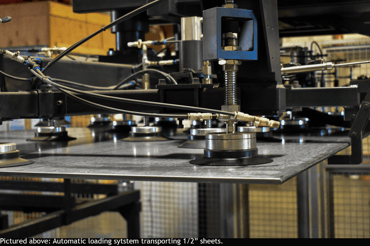

One of the first steps our material takes on its journey to becoming a quality machine is the Laser Department. Raw steel sheets are loaded onto the laser deck, where the machine then utilizes large suction cups to lift and move the sheet into position for cutting.

Our laser operators use special programming to "nest," or arrange, the parts. This minimizes waste by ensuring that the space available on the sheet of steel is used to the fullest extent possible.

The laser then cuts the steel according to the designated programming, and offloads the sheet skin after cutting. Our laser operators then manually remove the completed cut parts and discard the leftover steel skin. It's a fascinating process that combines the tech of today with the hard skills of our operators, and the result is custom steel parts of the highest quality - all produced in-house.

The laser cutting process was implemented seven years ago when we first introduced a 4kW Co2 Laser. This exciting new piece of equipment replaced our plasma cutter, which allowed us to begin streamlining our cutting process to keep up with the increasing demand for our machines.

Fast forward a few years from our first Co2 laser, and we upgraded that old workhorse to two fiber optic lasers. Today we operate 3 lasers between two manufacturing locations. Fiber optic lasers are a faster, more efficient and energy reducing solution. They utilize fiber optic cables instead of mirrors to effectively transmit the beam. They are able to cut up to 1” material at speeds ranging from 28 in/min up to 2,000 in/min, and they handle just about any project we can throw at them. Featuring an auto loading system, the lasers are able to run independently, even overnight, providing an increase in production and allowing our operators to expand and diversify their workload.

State of the art technology has also provided further freedom and efficiency for our engineering department. The accuracy with which the parts are laser cut eliminates extraneous fine tuning by hand, and it allows for more flexibility in design because we can change and test designs easily and swiftly. All of these elements combined allow us to uphold the Barreto promise of “Innovative Equipment Engineered to Last."

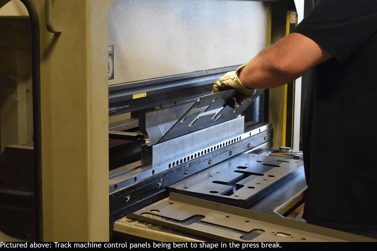

After cutting, a portion of the parts will move from the laser to the press brake. The press brake is a large machine that bends material using anywhere from 60 to 190 tons of force with startling accuracy. Our press brake operators carefully handle each and every piece of metal that goes into these machines, and they are trained to safely bend each piece according to specific measurements.

While the machines have advanced technologically, the press break has always had a prominent home at Barreto Manufacturing. In fact, our first press brake was built by Greg Barreto himself, and it was still in operation at our manufacturing facility until it found a new home in 2015.

The laser and press brake departments are just the first step on our manufacturing journey. To learn more about what it takes to be Built Barreto Tough, please subscribe to our blog.

This post was originally published in 2020 and has been refreshed and updated.