Building Barreto Tough: R&D and Engineering

In the next installment of our Building Barreto Tough series, we are going to shine a light on our Research and Development (or R&D as it’s commonly known) and Engineering departments.

-

Engineering

-

Development

-

Innovation

These departments work together to develop new products, and they also design and build the tools, jigs, and dies required to make the parts to manufacture them. These teams also work to improve on and continue to innovate existing designs by taking feedback from our employees, customers, and operators.

Engineering

Engineering

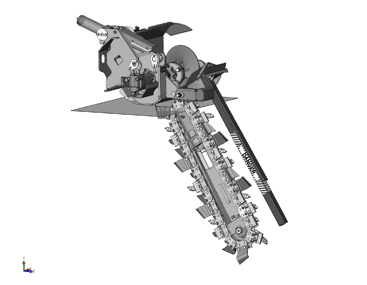

Our engineers take an idea or a concept and transfer them to a practical and realistic design using 3D design software such as SolidWorks®. With this technology both the Engineering and R&D departments can view, analyze, and modify machine designs throughout the process.

Development

During the development process for each of our machines and their component parts, prototypes are assembled and performance is tested and subjected to real life conditions. This enables us to create an innovative machine that is efficiently built and capable of handling the toughest of jobs. With an R & D department active in every aspect of our manufacturing, and familiar with the use and maintenance routines for each one of our machines, we are also able to ensure our machines are easy to operate and maintain.

Innovation

Barreto Manufacturing takes pride in our manufacturing process and our ability to keep our parts production and assembly in house.

That process is not limited to our equipment alone. Our R & D department is also responsible for creating many of our jigs for our robotic welding equipment, dies for our press brakes, and even machine lifts for our assembly line. Their ability to integrate our operations makes them a unique and important component tying our manufacturing family together.