Innovative Equipment Engineered to Last

Discover Barreto Manufacturing's 40 years of innovative, durable landscaping equipment, along with expert tips and local highlights for your projects.

Building Barreto Tough: CNC Mills and Lathes

Welcome to this installment in our Building Barreto Tough Series, where we give a bit of insight into what it means to be “Built Barreto Tough.” If you are just starting this journey with us, we recommend you start here: Building Barreto Tough: Laser Department and Press Break

This article focuses on our CNC department. An important, and rather busy, specialty in our manufacturing line!

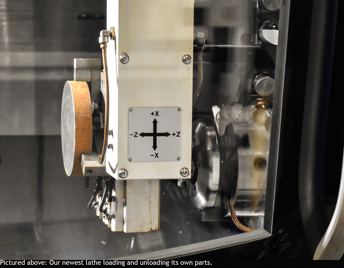

First off, what does CNC mean? CNC is defined as "computer numerical control." A CNC machine utilizes computer programming to shape material into a finished product. A CNC machine is a complex and intelligent tool that requires trained and careful operation by our talented machinists. CNC machinists are the operators of these impressive machines, and they load, unload, program, and monitor the processes.

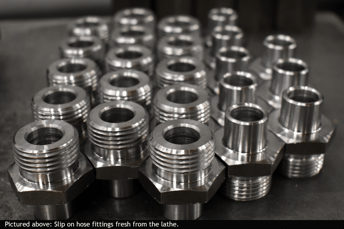

Our CNC department affords us the ability to fabricate many of the elements that make up our machines. We craft many in-house components, from bushings and bearing housings to internal and external gear parts on our lathes. We even process our own cutter wheels and hydraulic valve blocks on our mill machines. The CNC department has been an integral part of our manufacturing line for about 27 years, and the department has made great advancements in that time.

Years ago, when operating manually, the mill department was able to produce certain components at rates of about 75 units per week. The machines in operation today are able to produce those same individual parts at rates of thousands of units per week! The CNC department now operates 12 lathes and 5 mills between our Oregon and Idaho locations. Keeping up with advances in technology has given us the ability to increase our production speed and accuracy as customer demand grew. In-house production also allows us to control our own lead times and quality standards.

In addition to production, these advanced machines provide us the ability to machine more complex parts. The ability to produce whatever we need gives our engineers design flexibility and allows us to keep more of our manufacturing in-house. With the expanded workload and production, our machinists are able to learn and advance, which opens up entry level positions and allows us to offer apprenticeships to local high school students who show interest in machining and engineering.

Stay tuned for the next leg of our journey by subscribing to our blog.

This post was originally published in September 2020 and has been refreshed and updated.