Innovative Equipment Engineered to Last

Discover Barreto Manufacturing's 40 years of innovative, durable landscaping equipment, along with expert tips and local highlights for your projects.

Rotating Stump Grinder Teeth

Maintaining the teeth on your stump grinder is crucial to keeping your stump grinder in tip top operating condition. Inspection and replacement should be a part of your regular maintenance routine.

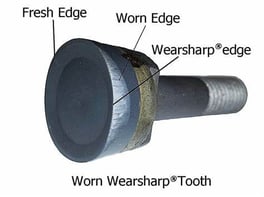

Barreto Stump Grinders are factory equipped with Greenteeth LoPro pockets and Greenteeth Wearsharp cutter teeth. We offer these sets in 500, 700, and 900 series. These cutter teeth are equipped with three cutting edges, allowing for increased longevity.

The following instructions will illustrate how to rotate these teeth to take advantage of each cutting edge.

1.Tools Needed

1.Tools Needed

- ½” Wrench (500 and 700 series)

- ⅝” Wrench (900 series)

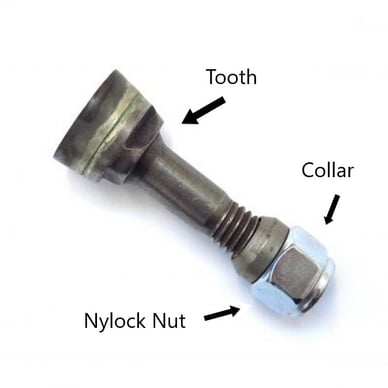

2. Greenteeth Components

If you are visibly noting wear (chipped or broken teeth, rounded edges), or noticing decreased performance from your wearsharp teeth, it is a good indication it is time to rotate them. Due to the high wear nature of these parts, and the vibration they are subjected to, we recommend you inspect your teeth after each use and check all fasteners weekly at a minimum. You will need to be familiar with the four components of the Greenteeth before you change or rotate them.

If you are visibly noting wear (chipped or broken teeth, rounded edges), or noticing decreased performance from your wearsharp teeth, it is a good indication it is time to rotate them. Due to the high wear nature of these parts, and the vibration they are subjected to, we recommend you inspect your teeth after each use and check all fasteners weekly at a minimum. You will need to be familiar with the four components of the Greenteeth before you change or rotate them.

a. The Pocket

Also referred to as the “holder”, the LoPro series pockets are an efficient, low profile pocket that the wearsharp Greenteeth fit snugly into. Each series of teeth has a corresponding pocket specific to its size. Note: a different series of teeth WILL NOT fit into another pocket. Example: a 900 series tooth WILL NOT fit into a 700 series pocket.

b. The Tooth

These are the guys that do the hard work. The Wearsharp tooth is designed with three cutting edges and a patented concave design for increased longevity.

c. The Collar

The collar, or “spacer”, is positioned opposite to the cutting edge of the tooth. It allows for a snug fit into the holder. Be sure you have reinserted the collars when changing teeth.

d. The Nut

The teeth are secured by a 5/16-18 nylock nut. The nylon allows for a locking nut without the use of loctite and provides the ability to change in the field.

3.Rotating the Teeth

Follow these simple steps to rotate your Greenteeth Wearsharp cutter teeth. The following instructions will be the same across all series sizes:

Follow these simple steps to rotate your Greenteeth Wearsharp cutter teeth. The following instructions will be the same across all series sizes:

- Using the appropriate sized wrench (see above), loosen the Nylock nut that secures the tooth into the holder (you do not need to remove the nut completely).

- Tap the tooth down enough that the tooth is free from it’s seat and can be rotated.

- Rotate the tooth a third of a turn.

- Reposition the tooth in it’s seat. The teeth are designed to rotate in thirds and should fit snugly back into the holder.

- Retighten the Nylock nut to proper torque specifications (see below for Greenteeth Wearsharp torque specs)

4.Torque Specifications

500 Series Wearsharp - 20ft lbs

700 Series Wearsharp - 20ft lbs

900 Series Wearsharp - 35ft lbs

For more torque specs and Greenteeth FAQs check here: Greenteeth FAQ.

As always, if you have any questions, feel free to call our service department at 1-800-525-7348.