Innovative Equipment Engineered to Last

Discover Barreto Manufacturing's 40 years of innovative, durable landscaping equipment, along with expert tips and local highlights for your projects.

How to Grind a Stump

Stumps in your yard or landscaping pose a difficult and costly problem if not dealt with correctly. Not only are they an eye sore and tripping hazard, but they are difficult to mow around and are nearly impossible to remove by hand. You can't afford to waste time and money with the wrong tools - hiring a professional or renting a stump grinder yourself will remove the stump for good and bring peace and functionality back to your space.

Whether you rent or own, the simple process of stump removal involves a little careful navigation to ensure a smooth removal that fully utilizes your robust stump grinding machine. In order to achieve the best possible results and minimize wear on the operator and the machine, follow along for some tips and tricks that will make a removal of any size a breeze.

1. DO:

- Ensure the work area is clear of obstructions and debris. You should be able to freely navigate the work area.

- Wear proper PPE such as eye protection, gloves, boots, and ear protection.

- Cut the stump down as close to the ground as possible - this saves you time while grinding.

- Ensure you have extra fuel on hand for big jobs.

- Familiarize yourself with the machine controls and user manual before starting.

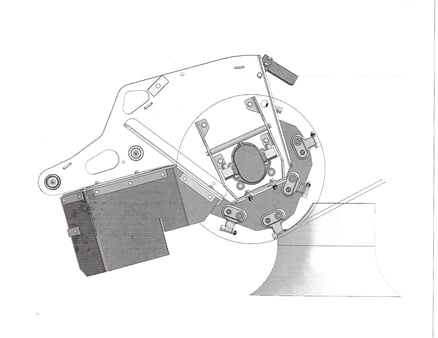

- Engage the chip shield equipped on the tracked Barreto stump grinders to prevent flying debris.

- Look for foreign material in the stump like nails, fencing, wire, or other materials the tree may have grown around.

- Ensure the machine is greased according to manufacturing instructions and before operating; especially the cutter wheel bearings which require daily greasing. (The machine is equipped with decals indicating the locations of the grease zerks).

- Operate at full throttle.

- Monitor cutting head and listen to engine speed. Both should maintain high speed.

- Take smooth, complete, lateral bites out of the stump.

DON’T:

- Don’t rush the job.

- Cut too deep into the stump on your initial or subsequent passes - you will know if you are cutting too deep if the engine bogs down or cutter wheel slows or stalls.

- Operate on a steep incline or near drop-offs or embankments.

- Come into contact with the cutter wheel - doing so will cause injury or even death.

2. Maintaining a Load on the Engine

One of our key recommendations for optimal stump grinder performance: Maintain a load on the engine. What does this mean? Maintaining a load on the engine means that the operator has struck the proper balance of leveraging the horsepower of the engine and the pressure of the hydraulics to the intensity of the cutting job.

When putting a load on the engine, you can hear the machine working and utilizing its horsepower. The goal utilization is found when the engine and hydraulics are working at pace with the job - if the grinder is working too hard because of a deep cut in the stump or the operator working the cutting head too quickly for the size of the bite, the engine will bog down, and the hydraulic pressure relief valve will automatically stall the cutter wheel. Stalling the wheel is not optimal, but the hydraulics protect the machine from damage in doing so.

When putting a load on the engine, you can hear the machine working and utilizing its horsepower. The goal utilization is found when the engine and hydraulics are working at pace with the job - if the grinder is working too hard because of a deep cut in the stump or the operator working the cutting head too quickly for the size of the bite, the engine will bog down, and the hydraulic pressure relief valve will automatically stall the cutter wheel. Stalling the wheel is not optimal, but the hydraulics protect the machine from damage in doing so.

If you’ve ever run a lawnmower through tall, wet grass, you have experienced what it means to bog down and stall a machine; the job becomes too much for the machine, and so the system is equipped to stall in order to protect the machine from overwork.

Hydraulics are meant to work - one of the many reasons we pioneered hydraulic use in our robust equipment. Resistance is what builds the hydraulic pressure, creating a respective fluid cushion on the system. The more pressure you apply to the cutter wheel when cutting the stump, the more you are utilizing the available power of the machine. By properly gauging the load on the engine, the operator can use the machine to the utmost of its capabilities.

3. Cutting Technique

Start slow. Raise the cutter head and move the machine into position by the stump. Engage the cutting wheel and slowly swing the cutter head across the edge of the stump. Adjust the cutting depth and swing speed to a pace that prevents the engine from bogging down and the cutter wheel from stalling.

After the first swing is complete, move the cutter wheel down 1/2" to 1", and repeat the swing. Continue making a series of cuts down the edge of the stump until the edge is cut to below ground level or the teeth are cutting at a depth below half the wheel radius. Depending on the diameter of the stump, you may need to move the machine forward to continue cutting.

It’s not a prescriptive science, but it is an intuitive process to remove a stump. Take inventory of the landscape and situation around you, listen to your machine, and adjust accordingly. Take time to practice the movements of the cutter head before you begin cutting. Then, enjoy the sounds of happy hydraulics working together with durable engineering to demolish the stump right before your eyes.