Innovative Equipment Engineered to Last

Discover Barreto Manufacturing's 40 years of innovative, durable landscaping equipment, along with expert tips and local highlights for your projects.

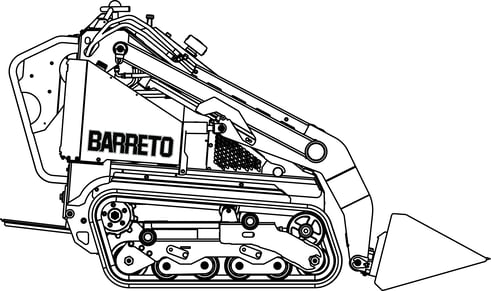

825TKL Mini Skid FAQ - Part 1

Some of the most frequent questions we get regarding our 825TKL are regarding our track system. If you’ve seen our machine, you have probably noticed the unique shape of our tracks. If you haven’t seen the 825TKL in action yet, check it out here: 825TKL Features.

Question: Why are the tracks on the 825TKL shaped like that?

Answer: To prevent de-tracking your machine.

In the time leading up to its release our engineers and assembly crew were working hard to solve the most frustrating problem our customers were facing with their existing mini skid steer units: De–tracking. There’s nothing worse than getting down in the dirt and throwing a track.

Our research showed us that the most likely conditions to cause a machine to de-track were turns performed in reverse, particularly in soft soil. With that challenge in hand, our team got to work!

On a normal track system, when operating in reverse, the tensioning spring is compressed allowing the upper side of the track to loosen and fall from the rollers.

Other companies:

Barreto:

Our unique hydraulic track tensioning system employs a hydraulic cylinder inside the spring, using fluid from the pump, to keep tension on the roller and the front of the track when maneuvering in reverse. This keeps constant pressure on the track operating in any direction and prevents de-tracking.

Here at Barreto Manufacturing, we are proud to produce tough, innovative equipment. That dream wouldn't be possible without the feedback and support of our loyal customers. If you have a topic you'd love to see us cover in our blog, email us at news@barretomfg.com.