Innovative Equipment Engineered to Last

Discover Barreto Manufacturing's 40 years of innovative, durable landscaping equipment, along with expert tips and local highlights for your projects.

Choosing a Log Splitter: Understanding How Log Splitters Work

If you’re ready to ease the burden and toss that splitting wedge and maul, a log splitter can be a great way to save time on your morning chores. Log splitters are fairly straightforward machines. But they do come with a few options and in a great number of sizes.

Understanding these basics can help you narrow down your selection:

Kinetic vs. Hydraulic

There are two types of log splitters currently populating the market. The most popular and widely used are hydraulic splitters. Kinetic splitters, while still used today, have not maintained the same amount of popularity since their introduction in the 1920’s.Hydraulic splitters employ the use of a hydraulic system and cylinder to steadily apply pressure to the wedge, causing the wood to split. Some models are able to split both horizontally and vertically. This vertical application allows for larger rounds that are unable to fit or be lifted onto the log splitter in a horizontal application. Hydraulic splitters can usually handle larger rounds, harder wood species, and wood cut in odd shapes. Though the cycle time on hydraulic splitters is noticeably longer than kinetic splitters, this adds an increased level of safety.

There are two types of log splitters currently populating the market. The most popular and widely used are hydraulic splitters. Kinetic splitters, while still used today, have not maintained the same amount of popularity since their introduction in the 1920’s.Hydraulic splitters employ the use of a hydraulic system and cylinder to steadily apply pressure to the wedge, causing the wood to split. Some models are able to split both horizontally and vertically. This vertical application allows for larger rounds that are unable to fit or be lifted onto the log splitter in a horizontal application. Hydraulic splitters can usually handle larger rounds, harder wood species, and wood cut in odd shapes. Though the cycle time on hydraulic splitters is noticeably longer than kinetic splitters, this adds an increased level of safety.

If you would like an in-depth look at log splitter hydraulics and how they work, Cylinder Services has produced a very interesting article on the subject: Log Splitter Hydraulics

Kinetic splitters are powered by the use of a flywheel. Instead of a steady application of pressure, they use the stored kinetic energy created by the flywheel to send a single quick burst of force to split the round. This makes their cycle time much shorter, though potentially more dangerous for a novice splitter. While they are not as efficient at splitting larger rounds, kinetic splitters are quite effective at splitting a number of smaller rounds very quickly. Kinetic splitters are also almost exclusively horizontal operation only, further limiting the size of rounds the splitter can handle.

Tonnage

You will likely hear hydraulic log splitters described by their tonnage. Some of the smaller models range from 4-6 tons, and larger models around 20-30 tons. Tonnage is the amount of pressure a log splitter applies to a piece of wood. Kinetic splitters are not able to be measured in tonnage, though oftentimes the manufacturer will provide an estimated comparison.

The tonnage of the log splitter can normally be found in the description or machine specs.

In the event you need to calculate that information, here’s an article that illustrates the formula: Hydraulic Cylinder Force Calculator

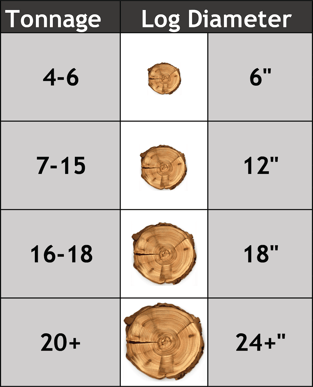

Tonnage is one of the key factors in determining what size round your log splitter can safely handle. Some smaller scale log splitters will be able to handle 6-12” diameter rounds, and the larger scale splitters can be capable of splitting rounds of 24” or more. The adjacent chart illustrates average capabilities for seasoned woods:

Wood Types

Knowing the types of wood you will be splitting will also have an effect on your log splitter choice. Seasoned woods will usually require less force to split than green woods. Green woods are trees that are freshly cut and have had little time to dry. Alternatively, seasoned woods have been dead and cut long enough to begin drying. Seasoned wood is also the ideal choice for firewood. If you will be splitting green woods more frequently, it would be advisable to go up a size on your log splitter.

Knowing the types of wood you will be splitting will also have an effect on your log splitter choice. Seasoned woods will usually require less force to split than green woods. Green woods are trees that are freshly cut and have had little time to dry. Alternatively, seasoned woods have been dead and cut long enough to begin drying. Seasoned wood is also the ideal choice for firewood. If you will be splitting green woods more frequently, it would be advisable to go up a size on your log splitter.

Wood species can also affect the efficiency of your splitting. Each species is rated by hardness, using what is called the Janka Scale. See this article from Bell Forest Product for further explanation and species ratings: Janka Hardness

The higher the rating the more dense your wood will be, which will require more pressure and force for splitting. Hardwoods and softwoods also burn differently, with each type having their own advantages in certain situations. For in depth information on firewood types and choices, check out this article from Morning Chores: Firewood Choices

Log splitters operate under extreme pressures and provide a great deal of force. Follow all operators guides and understand all safety precautions before operating your machine.